Metals

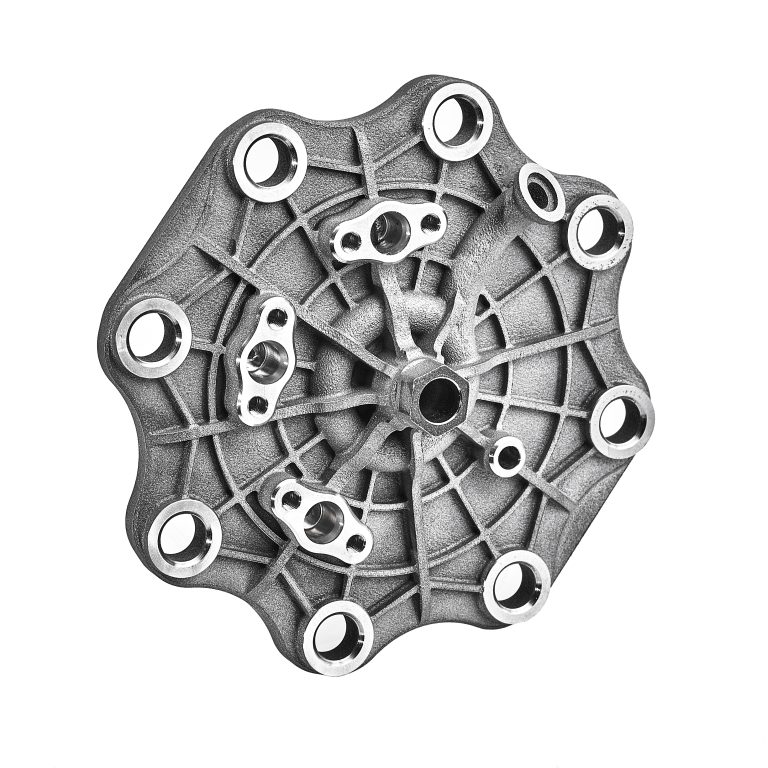

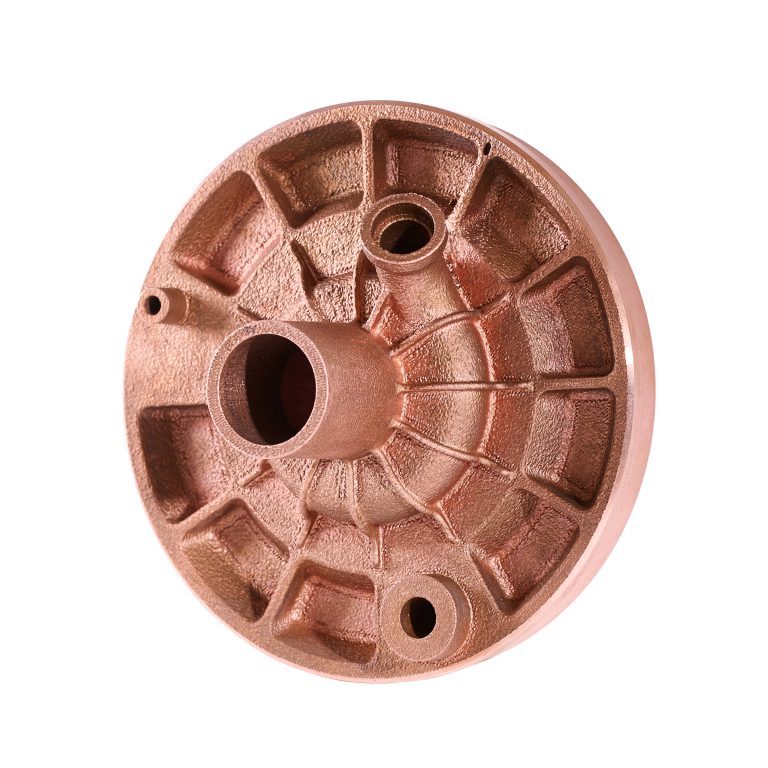

We specialize in the technology of additive manufacturing of three-dimensional metal objects – DMLM (Direct Metal Laser Melting) using a laser to melt ultra-thin layers of powdered metal. The most popular materials used in this technology are:

- titanium alloys,

- stainless steels,

- tool steels,

- nickel superalloys (such as In718),

- cobalt,

- chromium,

- aluminum alloys,

- surgical steels.

Objects obtained by this method are characterized by homogeneous properties.

We have the latest DMLM printer produced by Concept Laser from the GE Additive group – M2 Cusing Multilaser. This is the second generation of the well-known M2 Classic version on the market, with a working space of 250 x 250 x 350 mm, and laser power up to 2×400 W. The machine has several measurement systems that enable continuous supervision over product quality, repeatability and safety of the printing process. This high-class equipment enables engineers to conduct research projects in the area of additive technologies and to produce prototypes of aircraft engine parts, the development and introduction of which they are constantly working on.