Polymers

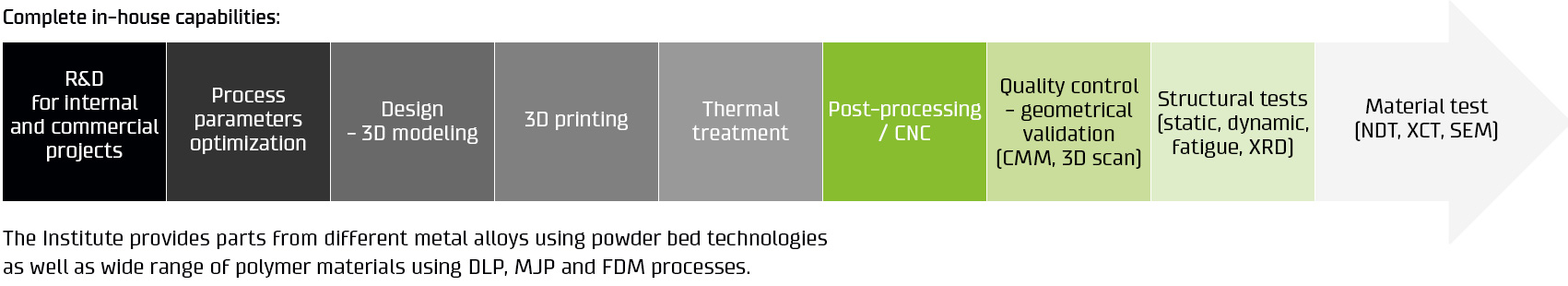

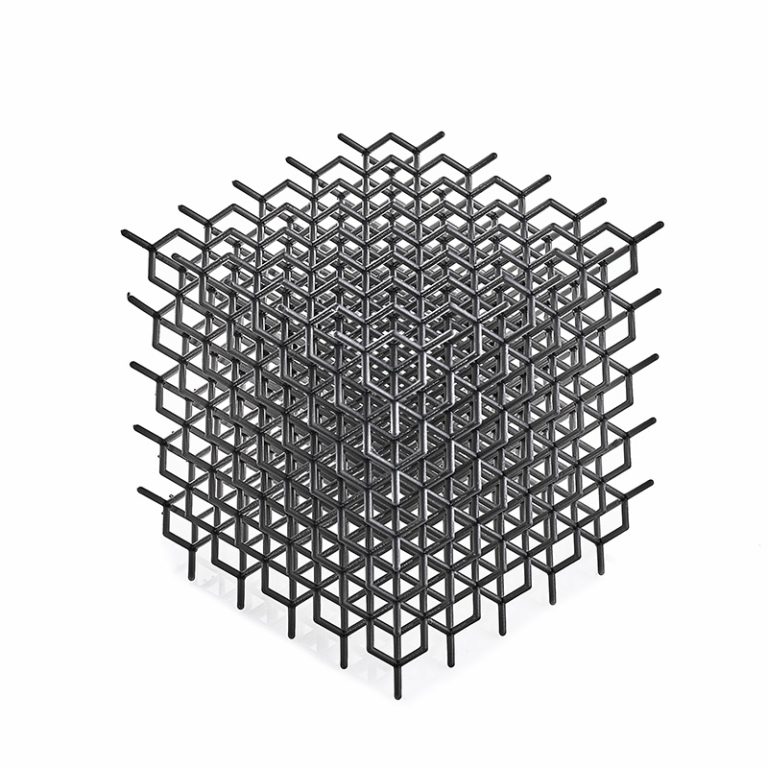

The offer of Łukasiewicz – Institute of Aviation within the framework of additive manufacturing technologies includes a comprehensive service of complete 3D printing in-house manufacturing process chain, targeted mainly for space and aerospace instruments. Many completed projects, specialized machinery and experienced engineering staff make the Institute’s offer unique.

Polymers

A wide range of polymer materials, including:

- Elastomers – production-grade rubbers

- High-temperature plastics – with heat deflection temperatures up to 300 °C, including material up to 150 °C that meets the UL94 – V0 flammability standard

- Composites – high-performance hybrid materials, production parts feature long-term mechanical stability in various environments

- ABS – strong plastic imitating injection molded material with long-term environmental stability

- High performance Ceramics (in development) -additive manufacturing using ceramic, metal, glass-ceramic resins/filaments.

- And others …

Key information:

- Isotropic properties

- Precision printing (diameter of internal channels from 0.15 mm)

- Threaded parts

- Excellent surface quality and repeatability

- Compatible with chemical and automotive fluids meeting UL94 V0 flammability rating

- ISO 9001

Scope of Services:

- R&D for internal and commercial projects

- Optimization of process parameters

- Design – 3D modeling

- 3D printing

- Thermal processing

- CNC machining/polishing

- Quality control – geometric validation (CMM, 3D scanning)

- Structural testing (static, dynamic, fatigue, XRD)

- Material testing (NDT, XCT, SEM)

The Institute supplies parts in various metal alloys using powder bed technology, as well as a wide range of polymer materials using DLP, MJP and FDM processes. Technologies

DLP – print volume 124.8 x 70.2 x 346 mm

MJP – print volume 294 x 211 x 144 mm

FDM print volume 360 x 360 x 360 mm