As part of one of the research directions of the Łukasiewicz Research Network, which is “Intelligent Mobility”, the Łukasiewicz – Institute of Aviation team together with its partners carried out the MOTOKOMP project. The aim of the project was developing a technology for the production of composite load-bearing structures for electric vehicles with the functionality of safe storage of vehicle batteries.

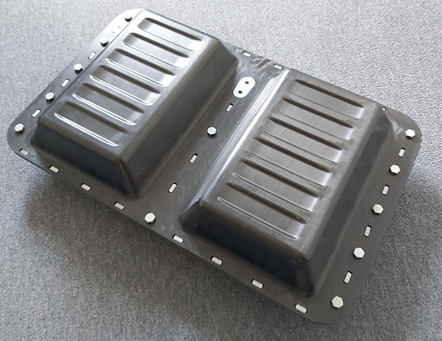

The process uses AFP (Automatic Fiber Placement) technology and pressing technology. The team of Łukasiewicz-Institute of Aviation implemented the assumptions of the additive manufacturing technology by producing a preform with the use of a robot, which was then consolidated into the final form using a high-temperature hydraulic press. After the production of a set of elements constituting the housing of electric cells, a technology demonstrator was assembled, which is the goal of the project.

Safe energy storage

The advantage of the developed technology is the reduction of the vehicle’s weight, which will allow it to increase its load capacity or take more batteries. The use of composite materials with a thermoplastic matrix reinforced with carbon fiber reinforcement allowed to combine the functionality of the load-bearing structure with a fire barrier, protecting the flame from escaping in the event of battery ignition.

The conducted flammability tests confirmed the non-flammability of the composite. At the same time, it was developed to protect the composite load-bearing structure with an elastomeric coating, doubling its impact resistance, which will positively affect the service life of the vehicles.

The MOTOKOMP project was implemented by the consortium: Łukasiewicz Research Network – Institute of Aviation (project leader), Łukasiewicz Research Network – Automotive Industry Institute (partner) and Łukasiewicz Research Network – Institute of Polymer and Dye Engineering (partner).

Recycling of composite materials

A continuation of the MOTOKOMP is a project with the acronym REKOMTER (Recyclicals of TERmoplastic Composites for battery protection applications).

As part of the project, it was planned to use production waste to produce electric cell casings, thus implementing the assumptions of the Zero Waste philosophy.

The first tests performed with the use of the equipment used in the MOTOKOMP project confirmed the thesis made at the beginning of the project, stating that production waste can be used to produce protective housings for electric cells.

—

The Łukasiewicz Research Network – Institute of Aviation is one of the most modern research facilities in Europe, with traditions dating back to 1926. The Institute closely cooperates with global tycoons of the aviation industry, such as: GE, Airbus, Pratt & Whitney, and institutions from the space industry, including the European Space Agency. Strategic research areas of the Institute are aviation, space and unmanned technologies. It also provides research and services for domestic and foreign industries in the field of materials, composite, additive, remote sensing, energy and oil&gas technologies.

The Łukasiewicz Research Network provides attractive, complete and competitive technological solutions. It offers a unique system of “challenging” to business, thanks to which a group of 4,500 scientists in no more than 15 working days accepts the business challenge and proposes the entrepreneur to develop an effective implementation solution. At the same time, it involves the highest competences of scientists in Poland and a scientific apparatus unique in Poland. What is most important – the entrepreneur does not bear any costs related to the development of an idea for research work. Łukasiewicz meets the expectations of business in a convenient way. The entrepreneur may decide to contact us not only through the form at https://lukasiewicz.gov.pl/biznes/ but also in more than 50 locations: the Łukasiewicz Institutes and their branches throughout Poland. They will receive the same – high quality – product or service everywhere. The Łukasiewicz potential is focused around such research areas as: health, intelligent mobility, digital transformation and sustainable economy and energy.